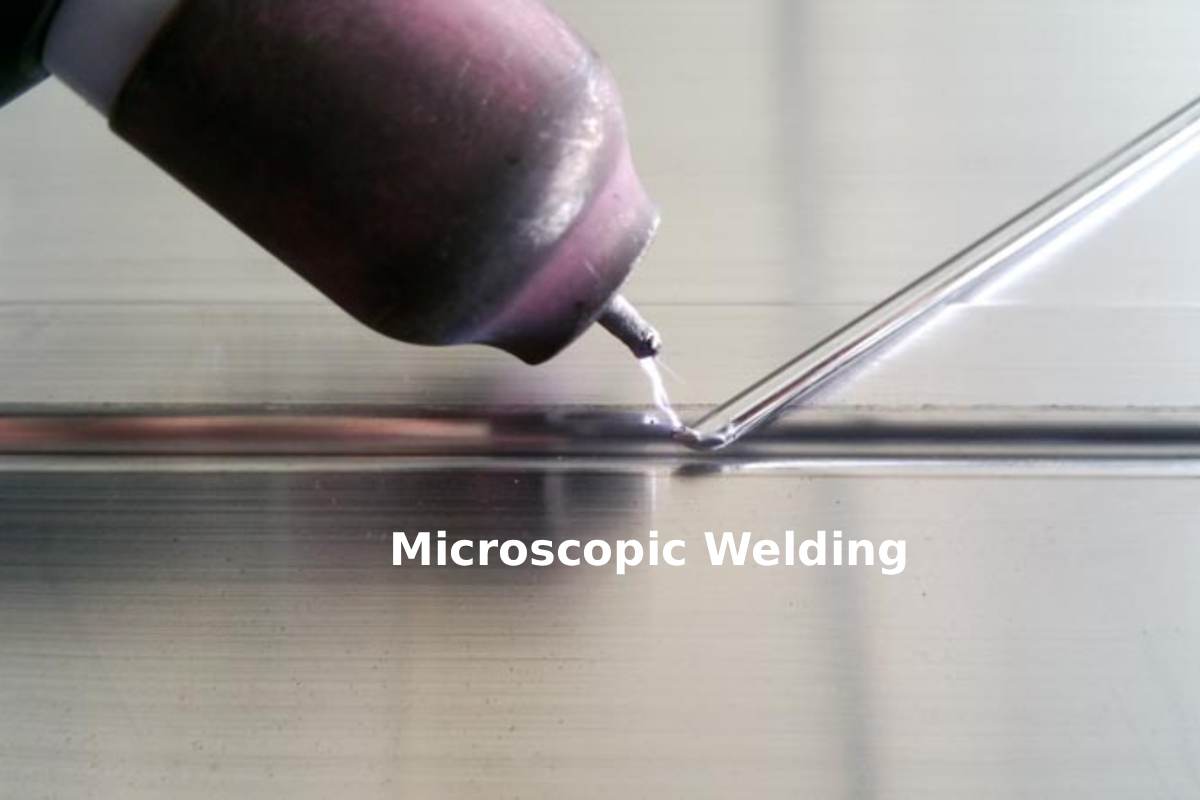

Precision welding for machinery isn’t a “nice-to-have” anymore. It’s the only language modern manufacturing and rework understand. Microscopic welding is no mere process; it’s the heartbeat of a new industrial rhythm. Once stuck in sterile labs for tiny assemblies, it now anchors massive production lines, finally bridging micro-accuracy with huge macro-output. It’s the secret sauce for building trust into metal, rock-solid reliability into microchips, and perfect repeatability into every single unit. In medical devices, electronics, and high-performance engineering, this tech isn’t background noise—it’s the invisible signature of perfection.

1. Precision at Scale: Where Speed Gets Tamed by Control

In the past, production lines had to sacrifice one virtue over the other, either move fast or stay accurate. Advanced Production Welding has become builders best option, by opening a new frontier where speed and precision finally shake hands. By delivering energy in pinpoint bursts, this tech keeps heat distortion and microfractures completely out of the picture, protecting every component’s core integrity.

That way, every single weld becomes a controlled event—not some thermal gamble. Even at relentless industrial speeds, the parts keep their geometry, their structure, and their promise. In production lines churning out thousands of cycles a day, this kind of precision is nothing short of revolutionary. It turns tolerance into an art form measured in microns, not those sloppy millimeters. The outcome? Repeatable perfection: identical results, no matter how hard you push the pace.

2. Data, Validation, and the Rise of Smart Manufacturing

Every welding spark has a story, and modern micro welding technologies are finally listening and translating. Every weld is meticulously tracked, analyzed, and dumped into digital archives, ensuring total process transparency. Pulse energy, penetration depth, and fusion data create an undeniable, traceable fingerprint for every single component. This is advanced quality control infused with digital, zero-doubt confidence.

Integrated with wider smart manufacturing systems, solutions like Microscopic Laser Welding actually turn the welding process into a self-aware, data-driven machine capable of self-diagnosis and predictive maintenance. For aerospace and medical fields, where documentation is literally law, MLW’s traceability becomes its strongest defense. Think about it: every beam of light creates both a weld and an iron-clad record of excellence.

3. Automated Consistency: Precision That Never Blinks

Sure, there’s a certain raw, ragged beauty to human craftsmanship, but automation simply blows that out of the water—it adds unmatched speed, laser-accuracy, and total consistency. Advanced micro welding solutions thrive in these fully automated environments. Imagine: robotic systems and CNC platforms synchronizing light, movement, and timing to surgical levels of accuracy. Every pulse, every weld, every tiny contour gets recorded and then repeated with mathematical, almost terrifying fidelity.

The bottom line? Zero quality drift. Zero guesswork. Manufacturers churning out high-volume, critical parts—like micro-sensors, connectors, or optical modules—rely on MLW because it delivers that promise of perfection 24 hours a day. It transforms a production floor into a true intelligent ecosystem: precise, predictive, and perpetually awake. It’s the machine that never misses.

4. Design Freedom: Building the Utterly Impossible

Traditional welding didn’t just limit imagination; it choked it dead. Now? Thanks to technologies like microscopic laser beam welding, whatever wild idea innovators dream up on paper is immediately achievable in reality, ready for instant testing and refinement. You want to fuse stainless steel to copper? Titanium to aluminum? Ultra-thin foils without distortion or discoloration? Consider it done.

Designers finally get to create the structures they once only sketched and filed away: lightweight, incredibly intricate, multi-material components that perfectly balance brute strength with delicate beauty. From miniature drone actuators to complex surgical tools, MLW is the indispensable, quiet collaborator behind the boldest ideas. It gives engineers unrestricted permission to innovate without the fear of structural failure. Honestly, it’s not merely joining materials—it’s the final step that connects raw imagination directly to reality.

5. The Medical Benchmark: Precision That Guards Life

In medicine, precision doesn’t just help; it saves lives. And consistency? That’s the ultimate guarantee. A single microscopic flaw is the difference between life-saving reliability and outright disaster. Advanced precision production welds are now non-negotiable in this realm, churning out pacemakers, neurostimulators, and implants that must function perfectly inside the human body.

The fusion is clean, contamination-free, and biocompatible, preserving both strength and absolute purity. This enables the creation of surgical tools that cut, guide, and heal with the exact same accuracy they were manufactured with. The truth is simple: MLW doesn’t just manufacture medical devices. It manufactures trust, one perfect pulse of light at a time.

6. Sustainable Efficiency: Restoring, Refining, and Revolutionizing

Microscopic Laser Welding is the ultimate weapon against industrial waste and all those messy inefficiencies that jack up operational costs. While quality control is mandatory, the tech achieves perfection in the very first weld. This drastically cuts down on rework, scrap, and expensive downtime.

Quality control is fundamentally flipped—it changes from passively finding flaws after they happen to actively guaranteeing integrity from the moment you hit the button. Crucially, advanced laser welding makes strategic restoration possible. When an expensive tool or mold breaks, replacement can halt production for months. MLW performs a precise, localized repair to the original specifications in just a fraction of the time, restoring performance in days.

This capability does more than just save money; it conserves vital resources and throws down a serious challenge to the old “throwaway” culture. It is a powerful, undeniable example of sustainability driven by smart, targeted technology.

Ultimately, microscopic welding has proven its transformative capabilities, making it more than a joining method to a manufacturing philosophy. It unites light, logic, and craftsmanship into a single disciplined force. By scaling precision without compromise, it transforms how industries think about production, reliability, and responsibility.

That way, MLW is transforming logic, where the smallest welds create the biggest impacts. Because the future of manufacturing doesn’t belong to those who weld to join, but to those who weld smarter — with precision refined to the power of light.