In today’s competitive business environment, optimizing warehouse and facility efficiency has never been more crucial.

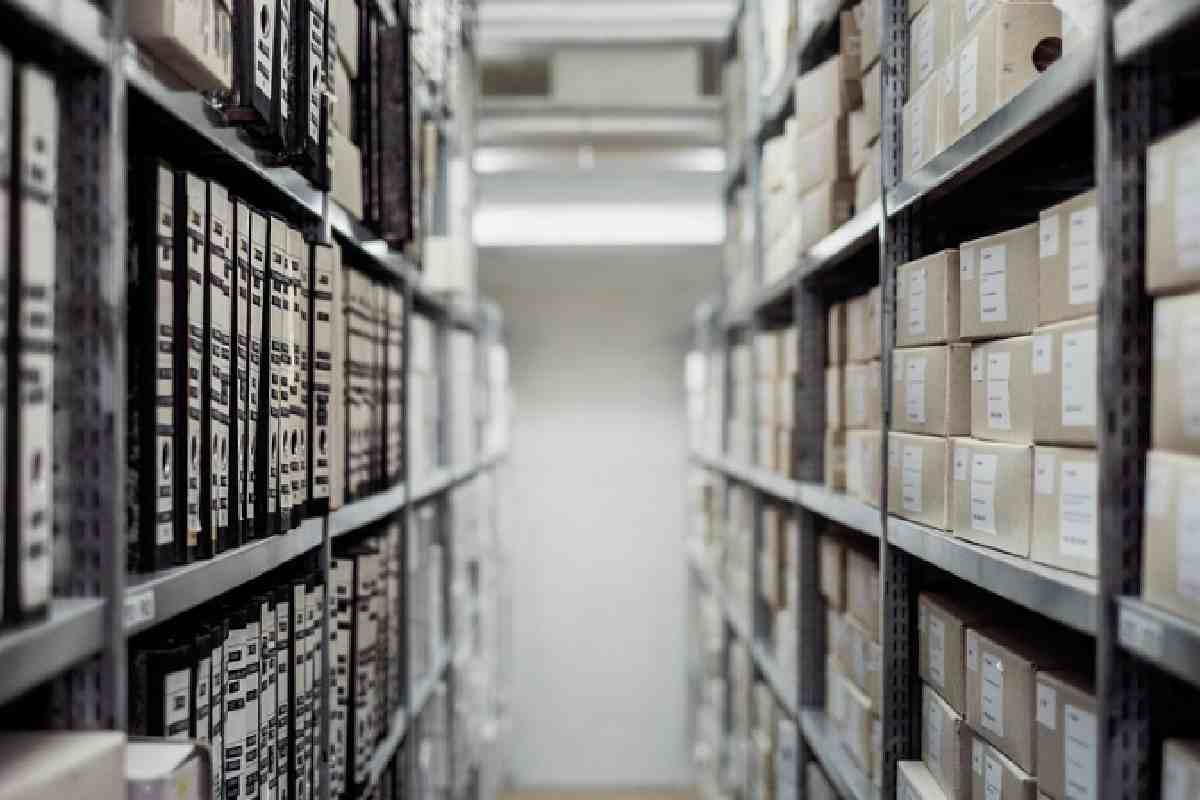

As real estate prices rise and pressure builds on companies to make every space count, companies are increasingly looking towards creative storage options. Container racking systems have become a revolutionary tool that can solve several operational issues while providing significant returns on investment.

Regardless of the type of warehouse you operate—whether it’s distribution, manufacturing, or retail —a well-designed, space-saving container racking system can transform the way you do things. These systems offer much more than just rack and storage – they are a comprehensive solution that can enhance productivity, save money, and contribute to a safer workplace.

1. Optimize Vertical Space Use: Break Through Floor Space Restrictions

With conventional storage practices, precious vertical space is often wasted, representing a significant loss of opportunity in facilities with limited floor area.

Container racking systems are designed to take full advantage of your facility’s full height capability, allowing you to store significantly more product in the same footprint.

Today’s container racking systems can reach heights of 30 feet or more, based on your building and safety needs. This vertical reach ability means you may be able to double or triple your storage capacity without expanding or relocating to a larger building.

The cost savings are enormous, as they avoid facility expansion or relocation costs while maintaining or even increasing inventory levels.

Key Advantages of Vertical Storage:

- Greater storage density: Store 200-400% more containers in the same floor area

- Lower real estate expenses: Avoid having to expand the facility or lease more warehouse space

- Better inventory accessibility: Systematic arrangement makes it easier to find and access items

- Better inventory visibility: Open sight lines and organized staging minimize lost or misplaced items

2. Lower Operating Costs Significantly

Up-front investment in container racking systems returns pay through several channels of cost reduction. In addition to the seemingly obvious cost savings from preventing facility expansion, the systems also contribute to operational efficiency, which directly adds to your bottom line.

Labor costs are one of the largest ongoing expenses in warehouse operations. Container racking systems optimize picking, packing, and inventory management processes, enabling your staff to do more in less time.

A structured organization eliminates time spent locating items, reduces walking distances, and minimizes handling errors that result in costly mistakes.

3. Installing Space-Saving Container Racking Systems in Your Facility

It takes professional evaluation and thorough planning to successfully install container racking systems. The process begins with a detailed facility assessment to determine the ideal positions, loads, and safety factors. This step is crucial to ensure your system meets current demands and long-term development expectations.

Installation Process Overview:

- Site preparation: Clear designated areas and ensure proper floor conditions

- Foundation work: Install anchor points and ensure structural stability

- Frame assembly: Build the racking structure as per the engineered design

- Safety integration: Add safety devices, guards, and compliance components

- Testing and commissioning: Perform load testing and operational qualification

- Staff training: Offer extensive training on system operation and safety procedures

There is a 2-5 day installation period, depending on system complexity and facility size. Professional installers minimize disruption to continuous operations, and work can be performed during off-hours or phased to allow the facility to maintain business continuity.

Post-Installation Optimization

After installation, the system requires adjustments to achieve optimal performance. This involves relocating your container to optimize the workflow, implementing inventory control methods, and planning service.

Continuous evaluation enables safe operation and also facilitates the development of further opportunities for optimization.

4. Improve Workplace Organization and Safety

Safety at work must never be compromised for the sake of efficient storage, and one of the best ways to achieve both is to install space-saving container racking systems in your facility.

These systems eliminate common warehouse hazards found in traditional storage setups—such as unstable stacks, falling containers, and cluttered walkways—while maximizing space and organization.

Industrial-strength container racking systems incorporate several safety features designed to protect both workers and inventory. The orderly layout also increases visibility within the facility, thereby lowering accident risk and enhancing overall situational awareness.

Safety Enhancements Include:

- Stack instability removed: Secure racking keeps containers from falling or moving

- Open pathways: Systematic storage ensures aisles remain clear and open

- Easier lighting: More efficient positioning of lighting is possible through better organization

- Less lifting injuries: Ergonomic design reduces strain on manual handling

5. Increase Productivity and Operational Efficiency

The capacity for use in inventory storage is only a small part of the organizational advantages of container racking systems.

The considerable advantages of container racking systems include the ability to practice advanced inventory management techniques, such as just-in-time delivery, first-in, first-out rotation, and automatic inventory tracking.

When containers are kept in designated, accessible areas, your workforce can locate and retrieve items quickly and accurately.

This improved efficiency trickles through the entire operation, from receiving and put-away to picking and shipping. The time saved across all these operations can have a significant impact on your facility’s overall productivity.

Productivity Improvements:

- Quicker inventory turnover: Proper storage allows faster movement of products

- Shorter order fulfillment time: Efficient picking processes accelerate shipping

- Increased accuracy: Systematic organization eliminates picking mistakes and returns

- Better scalability: Systematic organization accommodates business expansion

Conclusion

Container racking systems address several operational situations while providing measurable ROI. It enables you to utilize space more effectively, reduce costs, enhance safety, and achieve productivity improvements through a holistic approach to the current facilities management model.

The secret is finding a company with experience to evaluate your objectives, create the right system, and install it correctly, just like Space Aid Manufacturing. Once implemented correctly, your container racking systems will enhance your operation’s effectiveness, safety, and ROI, while positioning your operation for future growth.